On 7th July 2022, world-renowned journal Science published an online research paper titled “A processable, high-performance dielectric elastomer (PHDE) and multilayering process.” The first author of the paper, Dr. SHI Ye is currently a researcher and Assistant Professor of ZJUI. The corresponding author is Professor PEI Qibing, from University of California, Los Angeles. The paper reported the synthesis of new high-performance dielectric elastomer materials and a new process for producing multilayering devices (Figure 1).

▲Figure 1

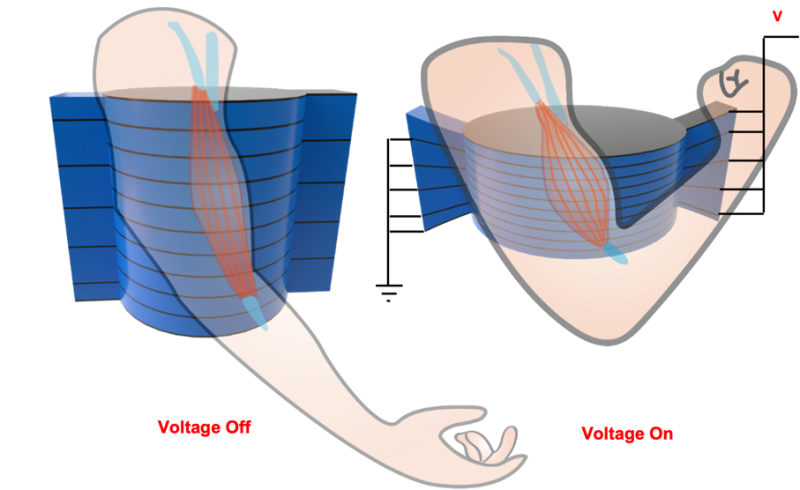

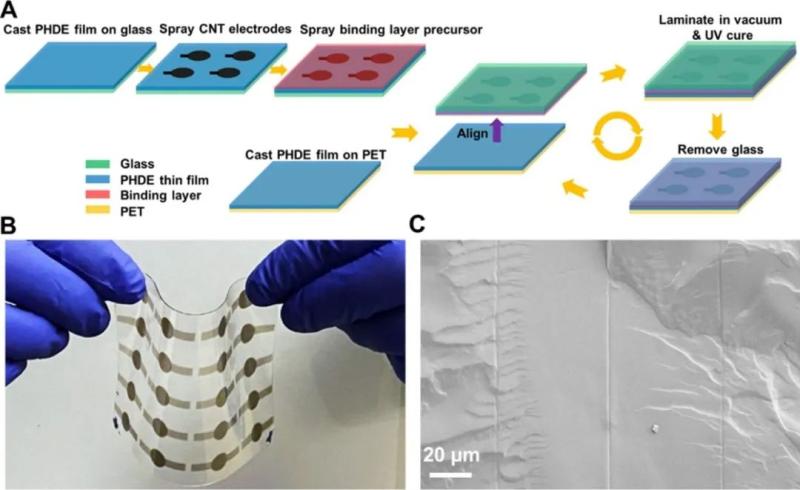

Dielectric elastomers (DEs), have the advantages of large deformation, high energy density, fast response speed. Therefore, they are widely used as artificial muscle materials in both academic research and practical applications. Dielectric elastomer actuator (DEA) is made by a DE film sandwiched between two compliant electrodes. Under a voltage, the electric field generates Maxwell stress, and compresses the film in the thickness direction and expands it in area. Currently commercial available 3M very high bond (VHB) acrylate tapes and silicone elastomer resins are the most widely used DE materials. However, they both have their drawbacks. VHBs suffer from high viscoelastic losses, and silicones tend to exhibit low maximum strains and dielectric strength. Additionally, many conventional soft elastomers often have electromechanical instability (EMI). Under constant voltage, the electric field increases as the DE film thickness decreases, resulting in progressively greater strain that proceeds until failure. One of the approaches to solve the problem is prestretching. However, this approach requires a rigid frame to maintain the applied strain, which decreases the processability greatly.

To solve the problems above, Dr. SHI Ye et al. designed a new type of processable, high-performance dielectric elastomer (PHDE), which can be compressed and stretched flexibly under electric stimuli. They built a bimodal-networked elastomer using two cross-linkers with different chain lengths (Figure 2) This material is soft initially and can be easily compressed to reach high actuation performance. After reaching a critical actuation strain, PHDE stiffens due to the stress on short chains in the network, thus being able to resist Maxwell stress, suppress EMI, and increase stability. Additionally, Dr. SHI Ye et al. introduced a small amount of additional hydrogen bonds into the network, which reduces the viscoelastic loss and increases its respond speed. PHDE exhibits a maximum areal strain of 190% and maintains strains higher than 110% without prestretching at 2 Hz. Correspondingly, the measured PHED energy density is 88J/kg and the power density is over 600W/kg. As comparisons, natural muscles show energy density ranging from 0.4J/kg to 40J/kg, and their power density is often lower than 100W/kg.

▲Figure 2

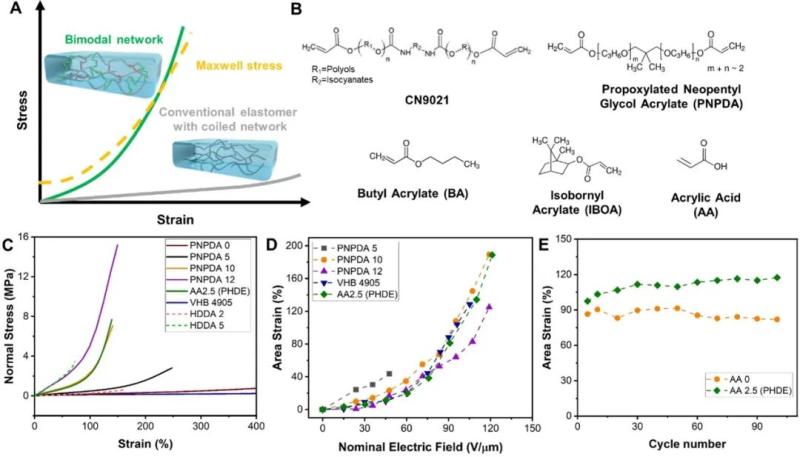

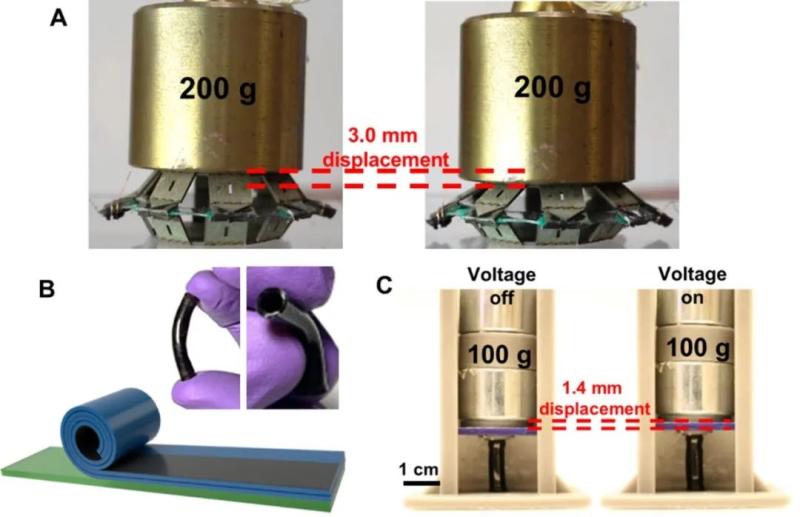

In order to increase the overall energy and power output of DEA, Dr. SHI Ye et al. developed a dry stacking method to produce multilayered DEAs (Figure 3). Compared with traditional wet stacking methods, this method has the advantages of high efficiency, compatibility with large scale production, high yield, and low loss of performance. The multilayered actuators maintained high response speed and reached strains of 110% at 2 Hz and 60% at 20Hz. Based on multilayered DEAs, Dr. SHI Ye et al. successfully fabricated spider actuators and multifunctional roll actuators (Figure 4), which demonstrates the promise of PHDE in various applications such as soft robotics, biomedical devices and wearable devices.

▲ Figure 3

▲ Figure 4

The first affiliation of the paper is UCLA, the second is ZJUI, and the third is SRI International from California.

Paper Link: https://www.science.org/doi/10.1126/science.abn0099

Article & Photo: Research team of Dr. SHI Ye

Editor: ZHANG Yi

Editor in charge: LI Yinan